Toyota Motor Corporation opens large battery-plant in the U.S.

Toyota Motor Corporation has opened a large battery plant in the U.S., making headlines across the automotive industry. New U.S. battery factory marks Toyota’s big step forward in the race toward vehicle electrification, signaling a bold commitment to electric vehicles (EVs) and hybrid technology. This development isn’t just a routine expansion , it’s a major milestone for Toyota and the broader EV market. In this article, we’ll explore why Toyota launches a major battery plant in the United States, what it means for the company’s strategy, and how it impacts the American EV landscape.

Key Highlights of Toyota’s New U.S. Battery Plant

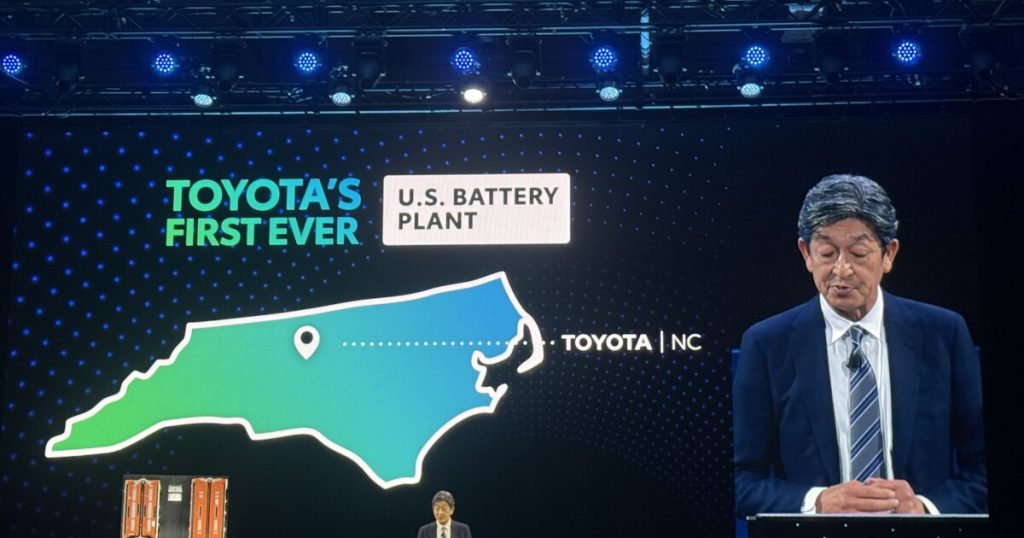

- Historic Opening: Toyota opens a large scale battery plant on American soil in Liberty, North Carolina, its first ever U.S. battery facility and 11th overall U.S.

- Massive Investment: The project represents a nearly $14 billion investment, with Toyota planning an additional $10 billion in U.S. manufacturing investment over the next five .

- Job Creation: The new battery plant shows Toyota’s growing EV commitment by creating 5,000+ American jobs, boosting the economy and manufacturing .

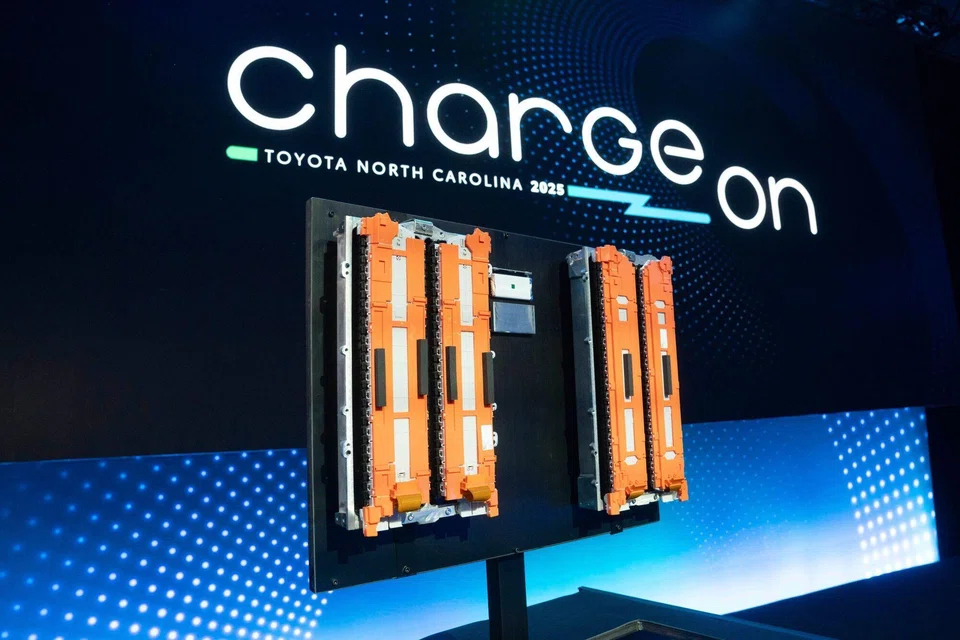

- Production Capacity: Once fully operational, the 1,850 acre site will produce up to 30 GWh of lithium ion batteries annually and host 14 production lines for hybrid and electric vehicle .

- EV & Hybrid Focus: Batteries from this facility will power popular Toyota models Camry, Corolla Cross, RAV4 hybrids and a forthcoming all electric 3 row SUV, reinforcing Toyota’s multi pathway approach .

With these points in mind, let’s dive deeper into why Toyota’s new battery plant boosts American EV production and how Toyota expands its U.S. footprint with the new battery plant to stay competitive in the evolving auto industry.

Toyota Launches Major Battery Plant in the United States

Toyota officially launched its major battery plant in the United States on November 12, 2025, with a high profile event at the new facility in Liberty, NC. This opening means Toyota Motor Corporation has opened a large battery plant in the U.S. that is now actively manufacturing battery packs. Production is already underway in fact, the first battery modules from the plant were shipped out months prior as the factory ramped up .The Liberty plant is the automaker’s first battery manufacturing venture outside its home country of , marking a significant shift in Toyota’s manufacturing strategy.

This state of the art battery factory is sprawling in scale and capability. Situated on 1,850 acres of land, the facility is so large and advanced that some have dubbed it a “mega site.” At full capacity, the plant can churn out 30 gigawatt hours (GWh) of batteries each year, enough to supply hundreds of thousands of electrified . The plant operates 24/7 to meet production and is designed to accommodate up to 14 production lines for battery packs of various sizes. These lines will manufacture lithium ion batteries for a range of Toyota’s electrified models from hybrid electric vehicles (HEVs) to plug in hybrids (PHEVs) and fully battery electric vehicles (BEVs). In essence, Toyota’s new U.S. battery plant is a one stop hub for EV and hybrid battery development and production, built to scale with the growing demand for cleaner vehicles.

Importantly, this isn’t just a factory in isolation; it’s part of Toyota’s broader commitment to “build where we sell.” By launching a battery plant on American soil, Toyota can produce batteries closer to its U.S. assembly lines like those in Kentucky and Alabama and reduce reliance on imported . Toyota begins U.S. battery production at this new mega facility with an eye toward strengthening domestic supply chains and shortening the distance from battery factory to car factory. This local production helps ensure that popular models like the Camry Hybrid, Corolla Cross Hybrid, and RAV4 Hybrid have a steady supply of batteries as consumer demand . It also positions Toyota to introduce new EV models more smoothly for example, an all new three row electric SUV is planned to be built in the U.S., and its battery packs will come straight from the North Carolina . By producing batteries in the United States, Toyota can speed up its EV rollout while potentially qualifying for government incentives that encourage local manufacturing .

A Major Milestone: Toyota Unveils New U.S. Battery Facility

This new U.S. battery factory marks Toyota’s big step forward in electrification and company executives aren’t shy about calling it a milestone. At the grand opening ceremony, Toyota Motor North America’s CEO Ted Ogawa heralded the launch as “a pivotal moment in our company’s history. For a company that built its reputation on the Prius hybrid but was seen as a late adopter of pure EVs, unveiling a dedicated battery plant in America sends a clear message: Toyota is serious about the EV transition.

Why is this such a major milestone? Firstly, it represents a concrete move from planning to execution in Toyota’s EV strategy. Toyota announced this project back in late 2021, and in just a few years it has come to . The facility isn’t just symbolic; it’s actively producing battery packs that will go into thousands of vehicles. This shows Toyota moving from theory to practice rather than just talking about EV commitments, Toyota built the infrastructure to support them.

Secondly, it underlines Toyota’s commitment to the United States market. By opening this battery facility, Toyota has expanded its U.S. manufacturing footprint significantly. It is Toyota’s 11th U.S. plant, but notably the first that is solely focused on . In terms of technology and scale, this plant puts Toyota on par with other automakers who have invested in U.S. based “gigafactories” for EV batteries. Toyota unveils the new U.S. battery facility as a major milestone also because it bridges a gap in Toyota’s portfolio previously, Toyota relied on battery suppliers and smaller in house production for its hybrids, but now it has a large scale, dedicated battery source domestically. This integration will help Toyota control quality, cost, and innovation for the batteries that power its future cars.

Furthermore, industry analysts view this moment as a turning point for Toyota’s EV stance. The company had long championed hybrids and was cautious on pure electrics, even as competitors like Tesla surged ahead. Now, with this U.S. battery plant, Toyota is effectively saying it’s fully joining the electric revolution on its own terms. “Toyota strengthens its EV strategy with the U.S. battery plant opening” is not just a headline it’s a statement that the company is aligning its considerable manufacturing might with the demands of the next generation of vehicles. This should boost confidence among customers and investors that Toyota will remain a key player in an electric future, rather than falling behind as the market shifts.

Toyota Expands U.S. Footprint with New Battery Plant

Building a $13.9 billion battery plant is as much an economic story as it is a technological one. With this project, Toyota significantly expands its U.S. footprint in manufacturing. The Liberty, NC facility cements Toyota’s presence in the American South, a region quickly becoming an automotive hub for EV and battery production. In fact, by investing big in the U.S. with the new battery operation, Toyota joins other auto giants who have recently launched battery factories in America’s heartland a trend spurred by both market forces and public policy.

From an investment standpoint, Toyota’s commitment is remarkable. The company initially committed $1.3 billion, then expanded the plan to nearly $14 billion as the scope . Beyond that, Toyota used the occasion of the grand opening to announce an additional $10 billion investment in U.S. manufacturing over the next five yearspressroom. This Toyota invests big in the U.S. with the new battery operation approach underscores how crucial the American market is to Toyota’s future. Executives noted that this will bring Toyota’s total cumulative U.S. investment to roughly $60 billion since the company established its operations in America decades In other words, Toyota isn’t just planting one facility it’s reaffirming that the U.S. is central to its global strategy, with continuous funding to grow production capacity.

The new battery plant also brings a significant boost to the local and regional economy. North Carolina, and the Greensboro/Liberty area in particular, will gain thousands of jobs from this single project. Toyota estimates the plant will create around 5,100 new jobs once it’s fully from technicians and engineers to support staff. Already about 2,500 workers are on site as production ramps , and that number will double in the coming years. This kind of job creation is a boon for the region, likely spurring further economic activity as the workforce grows. It’s no surprise that local and state officials were enthusiastic partners: North Carolina reportedly offered an incentives package around $600+ million in tax breaks, grants, and infrastructure support to secure Toyota’s. “History tells us when a company like Toyota plants their roots in a town like ours, that community is going to thrive,” said one local worker at the opening , reflecting optimism that Toyota’s expanded footprint will revitalize the area.

Another aspect of Toyota’s expanded presence is community investment. Alongside the factory, Toyota announced educational grants totaling $2.7 million to local . These funds aim to boost STEM education and workforce development in the region a forward looking move to train the next generation of high tech manufacturing talent close to home. Toyota is clearly playing the long game: by ingraining itself in the community and economy, it hopes to build loyalty and a pipeline of skilled workers. This deepens Toyota’s roots in the U.S. beyond just selling cars; it’s contributing to industrial infrastructure and knowledge in America.

Toyota’s New Battery Plant Boosts American EV Production

One of the most immediate effects of Toyota’s new plant is a boost to American EV production capacity. By producing batteries domestically at high volume, Toyota can accelerate output of electrified vehicles in its U.S. assembly plants. This helps not only Toyota’s own sales goals but also the wider adoption of EVs and hybrids in the American market. New battery plant shows Toyota’s growing EV commitment by ensuring that battery supply often a bottleneck in EV manufacturing will be more secure and scaled up onshore.

Consider the numbers: at 30 GWh/year capacity, Toyota’s North Carolina plant could supply battery packs for on the order of 300,000 or more electric vehicles annually assuming ~100 kWh per EV, or far more if used for hybrids which use smaller packs. These batteries will feed into popular models: Toyota confirmed that hybrid versions of the Camry, RAV4, and Corolla Cross will get battery modules from this dditionally, Toyota’s first U.S. built all electric SUV a three row family model will have its batteries sourced here as . By covering both hybrids and pure EVs, Toyota is leveraging the plant to maximize EV output across its lineup. Hybrids remain in high demand and can significantly cut fuel use and emissions, so supplying more of them with domestically made batteries is a win for customers looking for fuel efficient options. At the same time, the plant lays the groundwork for Toyota to scale up pure EV production without worrying about importing battery cells from Asia, which can be costly and subject to supply chain disruptions.

This domestic battery production also aligns with U.S. policy goals to build more EV components locally. In recent years, there’s been a push to establish an American EV supply chain for energy security and job creation reasons. Toyota’s move complements that trend – alongside other automakers who have built battery plants in states like Tennessee, Kentucky, Michigan, and Nevada. For instance, GM and Ford have their own multi billion dollar battery joint ventures in the works, and Tesla operates large Gigafactories in Nevada and Texas. Toyota entering the fray means the U.S. EV industry gets another major source of batteries, which could help ease the parts shortages that sometimes limit EV availability. It also fosters competition and innovation among battery manufacturers on U.S. soil, potentially driving advancements in battery tech such as improved range, faster charging, or new chemistries like solid state batteries in the future.

Crucially, the plant underscores Toyota’s evolving stance on electrification. For years, Toyota championed hybrid technology and was hesitant to dive fully into battery electric vehicles, citing concerns like charging infrastructure and customer needs. But as the market shifts, the new battery plant shows Toyota’s growing EV commitment in tangible form. The company can now produce the most critical component of EVs the battery in large volumes itself. This indicates a strategic pivot: Toyota is ready to compete in the EV era, not just with hybrid leadership but with serious BEV capabilities. The investment in American EV production capacity is thus both a practical step and a strategic signal Toyota is doubling down on electrification, not just dabbling in it.

Toyota Invests Big in the U.S. with New Battery Operation

It’s worth zooming out to appreciate how big Toyota is investing in the U.S. through this battery operation. The headline figure of $13.9 billion for the plant’s construction is one of the largest single manufacturing investments Toyota has ever made in the United States. In fact, this project alone rivals some automakers’ entire U.S. EV investment budgets. And Toyota isn’t stopping there the company’s pledge of an additional $10 billion over five years means we can expect even more expansion or new projects on American . These could include further expanding the battery plant, upgrading other factories for EV production, or even building a second battery facility if demand grows. By committing such a substantial sum, Toyota sends a message of confidence in the American market and workforce.

From a competitive standpoint, this level of investment is also about keeping up with rivals and government incentives. U.S. policies like the Inflation Reduction Act (IRA) have created financial incentives for automakers to localize EV supply chains including tax credits for EVs that use American made batteries and materials. Toyota invests big in the U.S. with the new battery operation partly to ensure its vehicles qualify for these incentives, making them more attractive to consumers. For example, an EV made by Toyota with a battery from North Carolina may be eligible for full federal tax credits, whereas an identical vehicle with an imported battery might not. Toyota’s $10B investment plan will likely cover sourcing more battery minerals domestically or from U.S. free trade partners, building charging infrastructure, and other steps to align with these policies. Essentially, Toyota is investing now to save costs and add value for customers later.

The economic impact extends beyond Toyota’s own operations. The new battery plant is expected to spur growth for suppliers and local businesses. Battery production involves a vast supply chain from lithium, nickel, and other raw materials to components like battery cells, casings, and electronics. We can anticipate some suppliers setting up nearby or expanding U.S. production to support Toyota’s plant e.g. companies providing battery separators, electrolytes, recycling services, etc.. Additionally, with thousands of new employees in Liberty and surrounding counties, everything from housing to retail stands to gain. Toyota’s operation could attract other high tech manufacturing to the region, creating a cluster effect. This is similar to how other big auto plants have transformed towns for instance, BMW in Spartanburg, SC or Tesla in Fremont, CA led to many supporting businesses around them. North Carolina’s Piedmont Triad region, traditionally known for furniture and textiles, may now become known for advanced battery manufacturing thanks to Toyota’s big bet.

Toyota Begins U.S. Battery Production at New Mega Facility

The fact that Toyota has begun U.S. battery production at this new mega facility is a significant operational milestone. Often, large plants take time to ramp up; Toyota’s North Carolina site is already producing battery modules as of . This means Toyota’s timeline from groundbreaking to production was relatively swift, reflecting effective project execution. For consumers and Toyota dealers, the start of production is welcome news: it implies that more hybrid and electric Toyotas can be rolled out without the delays that sometimes plague new EV releases which are frequently constrained by battery shortages.

In this early production phase, the plant is focusing on battery packs for hybrid vehicles, which are central to Toyota’s current lineup. According to reports, the factory’s initial output has been shipping to Toyota’s assembly plant in Kentucky and the Mazda Toyota joint venture plant in . These sites assemble popular models like the Toyota Camry Hybrid and Corolla Cross, so the batteries from North Carolina are already finding their way into American made cars. By covering hybrids first, Toyota is playing to its market strength Toyota sells hundreds of thousands of hybrids annually in the U.S. while gradually gearing up to tackle full EV batteries as new models come online. This phased approach ensures that the plant can fine tune its processes on the comparatively smaller hybrid battery packs before moving to the much larger packs required for long range EVs.

As production continues, Toyota plans to add more lines and capacity through the end of the decade. The company has stated that additional production lines will launch by 2030 to meet future . This suggests that Toyota is anticipating growing demand for its electrified vehicles and possibly preparing for next generation battery technology. By 2030, the plant might not only scale up quantity but could also shift to new battery chemistries for instance, Toyota has been researching solid state batteries; a breakthrough there could be implemented in this facility down the line. For now, though, the new mega facility is up and running, which in practical terms means Toyota has entered the club of automakers who produce their own batteries at scale in the U.S. a club that includes Tesla, GM , and Ford . This achievement is crucial for Toyota’s autonomy in vehicle production; it reduces exposure to overseas supply chain risks such as shipping delays or geopolitical tensions that could disrupt battery supply.

Toyota Strengthens Its EV Strategy with U.S. Battery Plant Opening

In summary, Toyota Motor Corporation has opened a large battery plant in the U.S., and this move strengthens its overall EV strategy dramatically. By having a major battery production base in America, Toyota aligns itself with the direction of the auto industry towards electrification, localization of supply chain, and sustainability. This strategic strengthening happens on multiple fronts:

- Product Strategy: Toyota can expand its EV and hybrid lineup more confidently, knowing the “heart” of the vehicle the battery is secured. We can expect new Toyota EV models like that upcoming 3 row SUV to launch in the U.S. with less delay, and popular hybrid models to be more readily available. The battery plant effectively supercharges Toyota’s ability to execute its electrified product plans.

- Competitive Position: In the face of competitors like Tesla with its U.S. Gigafactories and traditional rivals like GM, Ford, and Volkswagen all investing in EVs, Toyota’s U.S. battery plant ensures it won’t be left behind. Toyota is sending a signal that it intends to compete vigorously in the EV market. The move may even pressure other late moving automakers to follow suit in building battery plants to keep up.

- Market Impact: Toyota’s plant contributes to the broader ecosystem of EV manufacturing in America. More batteries and more EVs in the market will accelerate EV adoption among consumers by improving availability and potentially driving down costs through economies of scale. It also helps the U.S. move toward its goals of manufacturing leadership and reduced emissions in transportation. As Toyota’s new battery plant boosts American EV production, consumers benefit from greater choice and perhaps lower wait times for electrified vehicles.

- Environmental & Social Impact: By bolstering its EV strategy, Toyota is also indirectly contributing to environmental goals. Hybrids and EVs produced with batteries from this plant will reduce gasoline consumption and tailpipe emissions in the long run. Socially, the investment in jobs and education in North Carolina strengthens communities and showcases corporate responsibility. Toyota’s emphasis on training programs and STEM education funding shows it’s not just extracting value, but also giving back to the community building trust and goodwill.

Summary Table – Toyota’s New U.S. Battery Plant

| Category | Summary |

|---|---|

| Location | Liberty, North Carolina, USA |

| Opening Date | November 12, 2025 |

| Investment Size | Nearly $14 billion for the plant; additional $10 billion planned for U.S. manufacturing over five years |

| Facility Size | 1,850-acre mega-site; Toyota’s 1st U.S. battery plant and 11th U.S. facility overall |

| Production Capacity | Up to 30 GWh/year of lithium-ion batteries; 14 production lines at full build-out |

| Job Creation | Over 5,100 jobs expected; ~2,500 already hired during ramp-up |

| Battery Types | Lithium-ion for HEVs, PHEVs, and BEVs |

| Vehicle Models Powered | Camry Hybrid, Corolla Cross Hybrid, RAV4 Hybrid, and an upcoming 3-row all-electric SUV |

| Strategic Importance | Strengthens U.S. supply chain, reduces reliance on imports, supports IRA tax credit eligibility |

| Economic Impact | Boosts local economy, stimulates supplier growth, and expands Toyota’s U.S. manufacturing footprint |

| Community Investment | $2.7 million toward STEM education and workforce development in North Carolina |

| Production Status | Battery module production already underway; shipments sent to Toyota assembly plants in KY & AL |

| Long-Term Vision | Supports Toyota’s multi-path electrification strategy and future EV expansion (including solid-state research) |

Final Thought

Toyota’s launch of its large scale battery plant in the United States marks a defining moment not just for the company but for the entire EV landscape. This massive investment reflects Toyota’s transition from a cautious participant in the EV shift to a fully committed industry leader aligning its strategy with the future of clean mobility. By localizing battery production, strengthening supply chains, and expanding its U.S. manufacturing footprint, Toyota is setting the stage for accelerated electrification, increased vehicle availability, and long term innovation.

Beyond the vehicles themselves, the project fuels economic development, job creation, education, and technological advancement within the U.S. In short, Toyota’s new North Carolina battery plant is more than a manufacturing facility it is a strategic catalyst helping shape America’s electric mobility future.

References

- Toyota Motor Corporation – Corporate Press Releases

- Toyota Motor North America – Manufacturing & Investment Announcements

- U.S. Department of Energy – Battery and EV Supply Chain Initiatives

- North Carolina State Government – Economic Development & Incentive Information

- Industry Analysis from Automotive News, Reuters, and Bloomberg

Frequently Asked Questions (FAQ) for Toyota Motor Corporation Opens Large Battery Plant in U.S.

2. Why did Toyota choose North Carolina for its new battery plant?

Toyota selected Liberty, North Carolina due to strong state incentives, strategic proximity to its U.S. vehicle assembly plants, available workforce, and the region’s growing reputation as an EV manufacturing hub.

2. What types of batteries will the new facility produce?

The plant will produce lithium-ion battery packs for hybrid electric vehicles (HEVs), plug-in hybrids (PHEVs), and fully battery-electric vehicles (BEVs). It is also designed to support future battery technologies.

3. Which Toyota models will use batteries from this plant?

Models such as the Camry Hybrid, RAV4 Hybrid, and Corolla Cross Hybrid will use batteries from the facility, along with Toyota’s upcoming U.S.-built three-row all-electric SUV.

4. How many jobs is Toyota’s new battery plant expected to create?

The facility is projected to create over 5,100 jobs once fully built out, boosting local and state economies significantly.

5. How does this plant support Toyota’s EV strategy?

It strengthens Toyota’s EV strategy by securing domestic battery supply, reducing dependence on foreign imports, speeding up EV production, qualifying vehicles for federal incentives, and enabling expansion of Toyota’s electrified lineup in the U.S.